Dacia Logan MCV

Year:2008

Engine capacity:1.6MPI

Mileage:77200km

Opinion: This is the 5th car that ceramization is subjected to the process through the use of Ceramizer preparations. The first I used in the car Seat Ibiza 2.0 16V gasoline (opinion added on the site)

Unfortunately, I do not have compression pressure measurements before and after (I do not have time for this), because with the first car they only strengthened me that the preparation works! In the following cars:

Fiat Panda 1.1 gasoline 2006 mileage 80000km

Skoda Fabia II 1.2 TSI gasoline 2011 mileage 12000km

Skoda Fabia II 1.6 gasoline 2012 mileage 37000km

Currently ceramizuje Dacia :)))now 77450km In a moment (I have already bought a package of the next Ceramizers) Toyota Previa 2.4 gasoline 1992 year (!) mileage 310000km.

Always the same predictable effect. Silences the operation of the engine – cold and idling and while driving; silences the work of the power steering; fuel consumption decreases. Idle speed drops! Which makes it quieter at a standstill and the engine consumes less fuel. The most important task in my opinion Ceramizer – INCREASES DURABILITY!

Marcin Królak

Opinion sent on 08.04.2013

Dacia Logan MCV

Year:2008

Engine capacity:1.6MPI

Mileage:80800 km

Previously, the engine burned some oil, now it does not burn 🙂

The power steering made noise in the extreme positions of the steering wheel, now it does not make noise. The gearbox sometimes grinded now does not grind. Soon I was setting up a gas installation, I deliberately waited for the Ceramizers to start working especially in the engine 🙂 Since pouring Ceramizers (gearbox, engine, gasoline tank, steering) I drove over 3500km.

Feedback continued

The effect of Ceramizer on stabilizing the regulation of valve clearance.

Due to the characteristics of the internal combustion engine, valve clearance along with mileage is reduced by burning (degradation) of the valve seat material in the cylinder head. In practice, this occurs mainly in the case of exhaust valves due to much higher exhaust gas temperatures, their composition and pressure. This clearance usually decreases much faster when the engine is powered by propane-butane gas, the so-called LPG, sometimes even avalanche.

Ceramizer was used to limit this unfavorable process.

The car is Dacia Logan MCV 2008 year. Internal combustion engine powered by gasoline 95 or 98 okt 1.6 MPi Renault type K7M 710 mechanically converted at 76 600 km (engine top, all equipment and factory engine, new factory gaskets) from 85.6 hp to over 100 hp (torque increase by a similar value, GTA head). Car 5 seats.

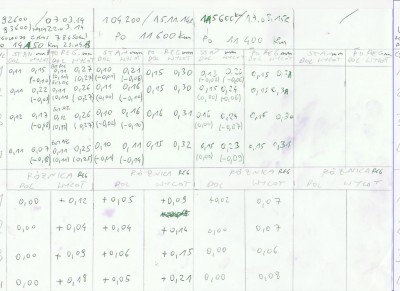

A number of measurements of valve clearances and activities were made, which are described below:

1. At a mileage of 77,200 km, 1 dose of Ceramizer was used for the engine.

2. With a mileage of 78 450 km, the valves were adjusted.

3. With a mileage of 82 250 km, an LPG gas installation (sequential STAG 4) was installed – a higher engine load.

4. At a mileage of 90,140 km, another second dose of Ceramizer was added to the engine.

5. With a mileage of 92,600 km, the valve adjustment was checked (14,150 km from the last adjustment).

Intake valve clearances unchanged

Intake valves:

1cyl 2 cyl 3cyl 4cyl

0,11 0,11 0,12 0,11

Exhaust valve clearances too small (results in mm)

Exhaust valves:

1 cyl 2 cyl 3cyl 4cyl

0,15 0,22 0,17 0,07

The standard for this engine is: intake valve clearance between 0.10-0.15mm; exhaust valve clearance between 0.25 – 0.30 mm.

The intake was left unchanged, the exhaust adjusted successively at 0.27 0.26 0.26 0.26 0.25.

6. With a mileage of 104,200 km, the valve clearance was checked again (14,150 km from the last adjustment). Intake valve clearances slightly reduced; exhaust valve clearances more even and slightly too small (results in mm).

Intake valves:

1cyl 2 cyl 3 cyl 4 cyl

0,10 0,11 0,10 0,10

Exhaust valves:

1 cyl 2 cyl 3 cyl 4cyl

0,21 0,16 0,16 0,11

Intake adjusted successively at 0.15 0.15 0.16 0.15 ; exhaust adjusted successively to 0.30 0.30 0.31 0.32.

7. With a mileage of about 105,000 km, cars were converted to 7-seat cars, which resulted in an increase in own weight and a greater load (most often occupied 6 places).

8. At 108,000 km, another third dose of Ceramizer was added to the engine.

9. With the mileage of approx. 112,000 km of hook was installed – thus almost every day a single-axle trailer was pulled and with a full load.

10. At 115,600 km, the valve clearances were checked once again. The clearances of the intake valves are almost identical, the clearances of the exhaust valves are even more even and only slightly too small – they almost fall within the factory standard (results in mm).

Intake valves:

1 cyl 2 cyl 3cyl 4cyl

0,13 0,15 0,16 0,15

Exhaust valves:

1cyl 2 cyl 3cyl 4cyl

0,24 0,24 0,24 0,23

Intake No. 1 adjusted to 0.15 remaining unchanged. Exhaust adjusted successively at 0.31 0.31 0.30 0.31

I also have an exact handwritten table made every time in the garage.

The results in the 2nd row are nothing more than the difference in clearance before and after adjustment (if such adjustment has occurred). Separate records for subsequent cylinders of intake and outlet valves.

APPLICATIONS

Ceramizer was used to stop the burnout (degradation) of the valve seat material. Here, in a specific engine, 1 dose of Ceramizer turned out to be too small to slow down this process. The engine, as I mentioned in the previous e-mail, is tweaked and powered by LPG. He works hard because I like fast and dynamic driving. Additional difficulties for the engine are air conditioning, 7-seater version and trailer pulling.

Subsequent doses and subsequent measurements indicate that Ceramizer has done a great job. After 3 measurements and 3 adjustments, which I carried out extremely carefully and meticulously also based on the original Romanian service manual for this engine (measurements were made each time at least 2 times; the accuracy of the chosen method is about 0.005 mm), the conclusions are as follows:

1. The process of firing the outlet valve seats in the engine cylinder head has been strongly inhibited. From the worst case, 0.18 mm to 0.09 mm, i.e. twice less material degradation at the socket/valve interface, in other cylinders also less.

2. In the first phase of measurements, the difference in degradation of the valve seat material in individual cylinders was very large and amounted to up to 0.15 mm, after the last measurement it can be seen that in each cylinder this process occurs almost equally.

3. Aligned operation on all four cylinders.

The gradual slowing down of the valve seat degradation process can be seen in the smaller and smaller differences between the nominal clearance and the clearance that actually occurred with each subsequent adjustment.

Difference at the second adjustment at 104 200 km of exhaust valves :

cyl 1 2 3 4

mm 0.09 0.14 0.15 0.21

The difference at the third adjustment at 115 600 km of outlet valves is only:

cyl 1 2 3 4

mm 0.07 0.07 0.06 0.08

Here you can see that the material valve and socket burn out in a minimal much smaller, despite less favorable conditions by loading the car and pulling the trailer, degree and evenly in each cylinder. Congratulations to Ceramizer!

Exceptionally 3 doses of Ceramizer were needed, you write about doubling the dose in the case of competitive driving. Here you can certainly write about such a thing given the load on the engine 🙂

Having seen a few years ago that Ceramizer works, I still persuade crowds of drivers, owners of cars, vehicles, etc. with internal combustion engines for a particularly long time, but usually also effectively also doubters and resisters of knowledge 😉 Greetings to the whole team!

Marcin Królak

Opinion sent on 2013-06-03 / Continuation of 2015-09-09