- TEST #1 : 562 HP WITHOUT OIL IN THE ENGINE

- TEST No. 2 PART 2: ENGINE OPERATION WITHOUT OIL IN TVN TURBO

- TEST #3: DRIVING WITHOUT OIL – NEW TEST (2018)

- TEST #4: OIL-FREE ENGINE PERFORMANCE TEST (CHINA)

- TEST #5: ENGINE REGENERATION WITH CERAMIZERS®, EFFECTS ON VEHICLE DYNAMICS

- TEST NO. 6 : CERAMIC REGENERATION OF THE ENGINE, EFFECT OF THE PREPARATION ON POWER

- TEST #7: EFFECT OF CERAMIZER® ON ENGINE POWER

- TEST #8: EFFECT OF CERAMIZER® ON OIL PARAMETERS

- TEST #9: CERAMIZER ON A MOTORCYCLE

APPLICATION IN INDUSTRY – read

TEST #1 : 562 HP WITHOUT OIL IN THE ENGINE

1. Compression pressure measurements and exhaust gas analysis before and after 2124 km from the moment of application of Ceramizers®:

Vehicle: Honda Civic: Reg. No. WF85817 year of manufacture 1992, mileage: 181350 km Engine no.: D15B26834351 Type: D15B7 (1.5i 16V), capacity: 1493 cm3 power: 75 kW (101hp at 5900 rpm and 124 Nm at 5000 rpm), LPG installation.

The measurements took place at CHMS Jacek Chojnacki, ul. Pruszkowska 32, 05-830 Nadarzyn. The SPCS 15 instrument was used for compression pressure measurements, for the analysis of exhaust gases analyzer type: TecnoTest mod. 481.

Compression pressure measurements:

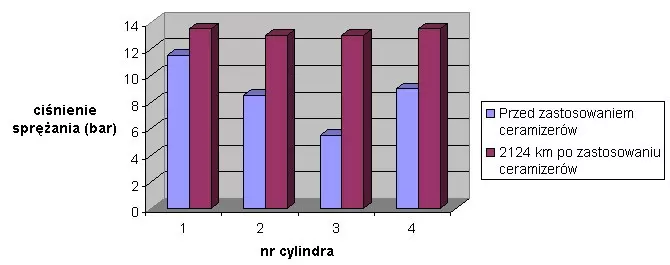

- On 18.10.2007, at a mileage of 181350 km before the application of Ceramizers® , compression pressure measurements were made.

- On 06.11.2007, at a mileage of 183474 km after 2124 km from the Ceramizer application® (2 doses to the engine and 1 dose to the gearbox), compression pressure measurements were made.

Measurements:

The largest increase (by as much as 136%) in compression pressure was achieved on the 3rd cylinder, i.e. from 5.5 bar to 13 bar.

The compression pressures before the application of ceramizers® on 3 cylinders were below 10 bar, this indicates a high wear of the engine. Ceramizer® caused an increase and alignment of the compression pressures to the nominal ones on all cylinders, thus regenerating the engine.

Exhaust gas analysis before and after 2124 km from the moment of application of ceramizers® showed a decrease in toxic exhaust components, i.e. a decrease in carbon monoxide (CO) of 17 %, a decrease in hydrocarbons (HC) of 20 % and a decrease in carbon dioxide (CO2) of 3,6 %.

A reduction in idle speed was observed from 1080 rpm to 920 rpm and at the same time the engine was equalized.

A change in the color of the electrodes of the candles to a brighter one was observed, which suggests a decrease in the “appetite” for the oil.

After measurements at 183474 km, the oil was poured and the engine (without oil) was started at idle in order to exclude possible defects before the actual oil-free driving test.

The engine idled for a total of 30 minutes without oil – 3 x 10 minutes each with 15 minute breaks.

Then the oil was poured and 1 dose of Ceramizer was added to the® engine.

The vehicle traveled another 1108 km with oil in the engine. In total, 3240 km were driven with the addition of Ceramizer® in oil (which is enough mileage to create a ceramic layer), so the test of driving without oil was started.

2. Oil-free driving test

On 14.11.2007, with a mileage of 184582 km (3240 km from the moment of Ceramizer application), a test of driving without oil in road conditions was started with an average air temperature of +1ºC.®

The engine was heated to operating temperature and then the oil was poured.

The engine was started and around 10 o’clock the vehicle set off on the route Nadarzyn (near Warsaw) – Katowice (Spodek) – Nadarzyn.

The exact course of the route without oil: E67: Nadarzyn-Mszczonów-Rawa Mazowiecka- Piotrków Trybunalski- E75: Kamieńsk-Częstochowa-Koziegłowy-Siewierz- road 86 Będzin- Katowice (Spodek) – Będzin- E75: Siewierz Koziegłowy-Częstochowa-Kamieńsk-Piotrków Trybunalski- E67: Rawa Mazowiecka-Mszczonów-Nadarzyn.

The course of the test was constantly observed, among others, by the editors of newspapers: Motor, Super Express and television: TVN Turbo and the Editors of the Motokibic TV Program – a program broadcast on TVP3 Katowice.

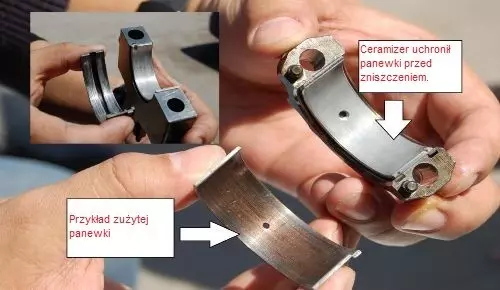

The demolition of the engine showed normal wear of the connecting rod shells (for an engine with a mileage of over 180,000 km), this consumption did not exceed the norm despite the mileage of 562 kilometers after oil was poured.

Test results:

- The vehicle drove 562 kilometers after pouring oil from the engine in urban traffic (5%) and outside the city (95%).

- The engine temperature during the test remained normal.

- The car moved at an average speed of 90 km / h, sometimes the speed was obtained – 120 km / h.

- The engine was powered alternately by gasoline and LPG (which further aggravated the extreme operating conditions of the engine).

- Despite several hours (a total of about 7 hours) of driving in extreme conditions, the engine still worked smoothly and did not create problems in the operation of the vehicle.

- The still operational and functioning engine was dismantled and handed over to assess the surface condition of the friction pairs.

- The wear of the connecting rod shells did not exceed the norm despite the extreme test that the engine was subjected to.

The result of the test of 562 km of driving after pouring oil from the engine confirms the effective action of Ceramizer® in protecting engines against wear and presents its unique properties. We strongly want to emphasize that the purpose of the test was to examine the effect of ceramizer® on the protection of the friction surface (in no case was the purpose of the test to show that it is possible to drive without oil and it is unnecessary). The oil was poured to create unusual, extreme engine operating conditions. Due to the extremeness of the test, we strongly advise against performing similar tests on your own vehicle.

Articles about the test:

TEST NO. 2 PART 1: DRIVING WITHOUT OIL ON TVN7 (PROGRAM “ON THE AXIS”)

In the automotive program “On the axis” broadcast by TVTVN 7, Ceramizers® and a test of 300 km of driving without oil in the engine were presented.

At the beginning of the test, measurements were made to show the condition of the engine (compression pressure in the cylinders), after which Ceramizers® were applied to the power unit.

Re-measurements of the engine after driving 2000 km from the moment of application of the Ceramizers® showed an increase in compression pressure, which indicates the regeneration of the engine.

Then, in order to exclude possible defects before the actual test of driving without oil – the drained oil and the engine worked without oil at idle for about 30 minutes, after which the oil was flooded and another dose of Ceramizer® was applied.

When the vehicle drove another 1000 km, an extreme test was finally undertaken. The oil was drained from the engine and the vehicle was used in urban and out-of-town driving.

After about 300 km of driving without oil in the engine, the test was completed.

Diagnostic tests of the engine after this stage showed that the compression pressure and oil pressure in the oil pump thanks to the use of ceramizer® remained unchanged, despite 300 km of driving without oil in the engine! A working engine is still in normal operation.

The result of the oil-free driving test confirms the effective action of Ceramizer® in protecting engines against wear and presents the unique properties of Ceramizers®, but due to the extremeness of the test, we strongly advise against performing similar tests on your own vehicle.

TEST No. 2 PART 2: ENGINE OPERATION WITHOUT OIL IN TVN TURBO

The engine of the tested Polonez, which in 2005 traveled 300 km without oil in the engine, still worked despite the extreme test it was subjected to. So oil was poured into it, another Ceramizer® was added and the vehicle was used for the next 8 years to transport construction equipment.

In 2013, together with TVN Turbo, a final test was carried out. Oil was poured from the engine, the bowl was removed and the engine was started at idle (“clearance”).

The engine lasted 3 hours 35 minutes without oil , which is equivalent to about 172,000 revolutions of the crankshaft. The total result of the test without oil is 300 kilometers in the engine and an additional 3 hours 35 minutes at idle.

TEST NO. 3 : DRIVING WITHOUT OIL – NEW TEST (2018).

TEST #4: OIL-FREE ENGINE OPERATION TEST (CHINA).

Vehicle: Suzuki (petrol)

Registration number: Liao B 88A77

Year of Build: 2008

Mileage: 143 342 km

Engine: K14 displacement: 1372cc

Power: 67 kilowatts

Test site: Liaoning Province, Dalian, Xigang

Test apparatus used: pressure gauge for measuring compression pressure in cylinders

I STAGE OF THE TEST

The first stage of the test was to measure the compression pressures before and about 2000 km after the use of Ceramizers®.

- Pressure measurement made before the application of Ceramizers®, made on: 25.03.2012 with mileage: 140.240 km

- Pressure measurement about 2000 km after application of Ceramizers®, made on: 05.04.2012 with mileage: 142.240 km

Before Ceramizer® preparations were added, the compression pressures in cylinders 1, 2, 3, 4 were uneven. The use of Ceramizers® raised and equalized the pressures to 13 bar (by an average of 24%). Ceramizer® sealed and restored efficiency in the piston-cylinder system.

STAGE II OF THE TEST

To assess the effectiveness of Ceramizer® in protecting the engine against wear – a test of engine operation without oil was performed.

The engine worked without oil for a total of 30 minutes (3 times 10 minutes with 15 minute breaks). Before the test, the car drove a® total of 3100 kilometers with Ceramizer CS applied (in the amount of two doses), which is a distance sufficient to form a suitable metal-ceramic layer on the friction surfaces.

Date: 16.04.2012, outdoor temperature + 18oC – engine oil is already flowing from the oil sump.

.

.

At 11:00 a.m., the test car is already devoid of lubricating oil.

11:30 a.m. – the engine is running without lubricating oil.

After 30 minutes of engine operation without oil, the protective effect of Ceramizer® on the power unit was confirmed thanks to the unique properties of the preparation. The still operational and functioning engine was dismantled and handed over to assess the surface condition of the friction pairs. The wear of the connecting rod shells did not exceed the norm despite the extreme test that the engine was subjected to.

.

.

Summary:

- Compression pressures after the use of Ceramizers® increased by an average of 24%, which indicates the regeneration of the engine.

- The operation of the engine without oil for 30 minutes did not destroy the friction surface – which indicates the formation of a protective ceramic-metal layer on the friction surfaces.

TEST No. 5 : ENGINE REGENERATION USING CERAMIZERS®, EFFECT ON VEHICLE DYNAMICS.

The tests were carried out at the Industrial Automotive Institute in Warsaw, and the tested car is Daewoo Nexia.

Vehicle: Daewoo Nexia

Engine Mileage:179tys 407km

25.03.2004

The first visit to PIMOT took place, measurements were made of pressures of the end of compression (showing the condition of the engine) and vehicle dynamics (acceleration of the car from 60 to 140 km / h in V gear). Then we applied Ceramizers to the® engine and gearbox.

.

.

14.04.2004

After driving 2654 km (since the use of Ceramizers), measurements® were made again.

Measurement of compression end pressures with the throttle open showed an increase and alignment with the nominal pressures in all cylinders. A maximum increase of 1.8 bar, or 16.3% of the compression end pressure on the fourth cylinder, was achieved, to put it another way, the engine practically returned to its factory condition. This is accurately illustrated by the chart and table below.

Thanks to the use of ceramizers® , we also achieved a 9.9% increase in vehicle dynamics when accelerating from 60 to 140 km / h in V gear.

Additional feedback from the owner (date of receipt of the opinion 18.03.2006)

As a former owner of the tested Nexi at your PIM-ot, I wanted to describe further impressions of using the car.

The behavior of the car after adding the agent (mileage of about 180 thousand) is described on your website. I sold the car with a mileage of 260,000 km. At the same time, I applied ceramizer to the gearbox. Returning to the engine at a later stage, he did not take oil AT ALL. He worked quietly and accelerated well. I did not add any other means after applying ceramizer. The car was operated further on a semi-synthetic, and oil changes were carried out every 8-9 thousand km. The compression of the engine at 230,000 km was almost identical to that of the Ceramizer® at 190,000 km. Unfortunately, he does not have a printout (this was done at a friend’s during the working hours of the service). The car continues to serve the next owner without a problem. All the time operated on gas and makes a month about 4000-5000 km. A day, the car drove 2-5 hours, sometimes without turning off the engine. When processing with the preparation, I used a misunderstood more thorough than recommended 🙂 Well, the first 1000-1200 km I did not exceed 2800 revolutions. Perhaps this resulted in better achievements of the preparation.

As for the gearbox : did not enter too much 2 and 3 gear. After pouring the preparation (2 doses) and following the recommendations – the runs began to enter gently after driving about 200-300 km, then it became perfect after 1000-1200 km. Before adding the preparation, I changed the oil in the box without adding any other preparations. I must admit that at 230,000 km I changed the clutch, but apart from the more flexible clutch pedal, I did not observe an improvement in 🙂 Conclusion that ceramizer helped. The drained oil from the box turned out to be quite fresh and clean. As I later found out, the previous owner also changed it. The possibility of the influence of new oil is eliminated here. I applied Ceramizer to the box at a mileage of about 195 thousand km.

Regards Mariusz

TEST No. 6 : CERAMIC REGENERATION OF THE ENGINE, EFFECT OF THE PREPARATION ON POWER.

Carried out on a dynamometer

Vehicle: 1991 Honda Civic 1.6 16v

Engine mileage: 234tys 683km

Registration No: WI 92009

Ceramizer® was used for the engine and gearbox.

The oil was previously changed about 1500 km before using Ceramizer® at 233050 km.

The first measurement was made before the ceramizer was® used – with a mileage of 234683 km.

The second measurement was made after using Ceramizer® and covering about 1400 km – with a mileage of 236083 km.

Results:

1. The maximum increase of 3 kG/cm2 or 26.3% of the pressure of the compression end was achieved on the 3rd cylinder.

2. Increase to nominal values and equalization of the pressure of the end of compression in all cylinders, in other words, the return of the compression pressures of the engine to the practically factory state of the new engine was achieved.

3. Increase in maximum torque Nmax by 3 Nm (affecting vehicle dynamics).

4. Increase in Pmax power by 2 PS (affecting vehicle dynamics).

Diagrams of torque N and power P as a function of engine speed:

Summary of compression end pressures (left before ceramizer® application right after application):

TEST #7: EFFECT OF CERAMIZER® ON ENGINE POWER.

Vehicle: BMW 330 D from 2000

Engine mileage: 270 thousand. Miles.

Registration No: AA-VM 746

2 Ceramizers for the® engine and a fuel refiner were used (which eliminated the irregularities of the injectors). After driving 3782 km from the moment of application

Ceramizers – the® engine obtained the following results on the dynamometer:

- An increase in maximum power by 4.66%, i.e. by 7.7 HP (5.7kW).

- Increase in maximum torque by 3.2%, or 13 Nm.

- Increased flexibility and dynamics of the engine – this is due to the shift of torque characteristics to lower revolutions.

The increase in power and torque was achieved over the entire range of measured engine revolutions and at 2800 revolutions per minute the largest increase in power was achieved – 9HP and the largest increase in torque – 24Nm.

TEST No. 8 : EFFECT OF CERAMIZER® ON OIL PARAMETERS.

Ceramizer® does not change the physicochemical and rheological parameters of the oil, i.e. it is neutral to the oil.

This is confirmed by the expertise of the AIR FORCE INSTITUTE OF TECHNOLOGY NO. 6/55/08 (PDF format).

In practice, this means that Ceramizer® can be applied to any oil while using the parameters that the oil recommended for a given mechanism has.

Experiment NO. 6/55/08:

1. LEGAL BASIS

Order dated 2008.01.29 from the company “VIDAR”, 00-717 Warsaw ul. Czerniakowska 58.

2. OBJECT OF WORK

Tests of Orlen Classic SJ/CF 15W/40 engine oil with “Ceramizer®/”Pan Mechanik” and Orlen Classic SJ/CF 15W/40 engine oil without preparation within the agreed scope.

3. PURPOSE OF WORK

Assessment of the effect of “Ceramizer®/”Mr Mechanik” on the basic physicochemical properties of engine oil.

4. TIME AND PLACE OF WORK

02.02.2008 – 10.03.2008

Department of Propellants and Lubricants (Z-55) ITWL.

5. WORKFLOW

The scope of the research has been agreed with the Work Client (Table 1). Samples for testing were provided by the Customer. The oil preparation was introduced in the amount prepared by the Customer.

The oil with the preparation was mixed using a low-speed agitator (about 200 rpm) for 3 hours at a temperature of about 60oC.

Sample numbers:

- engine oil – 0039-08

- engine oil with additive – 0040-08

The results of the study are presented in Table 2. The test results obtained refer only to the tested samples.

In the entire range of tests performed, no significant changes in the parameter values for the sample of engine oil with additive were found in relation to the parameters of engine oil without additive. This indicates a neutral effect of the tested additive on the basic physicochemical properties of the tested engine oil.

6. CONCLUSION

On the basis of the performed tests, it can be concluded that the tested sample of the additive “Ceramizer®/”Pan Mechanik” after the introduction into the engine oil (the supplied sample of Orlen Classic SJ/CF 15W/40 oil) does not adversely affect its basic physicochemical properties.

DEVELOPED

Ph.D. Jerzy Zielinski

TEST #9 : CERAMIZER® ON MOTORCYCLE

.

.

.

.  .

.  .

.

.

.

.

.  .

.  .

.

.

.

.

.

.

.